The AsperCut

In the spring of 2023, the French start-up SYLEKTIS tested and presented to producers its new robot for the selective harvesting of white asparagus, the AsperCut.

It was an opportunity to present the AsperCut to farmers, to gather their impressions and to discuss the improvements to be made for the future. A big thank you to all the producers, to our hosts, Copadax, Maisadour, the Pallin family, Fleuron D’Anjou, Benjamin Marchal, Planète Légume, Asperges d’Alsace, Christian Befve&Co and all those who supported us.

This second version of the prototype allowed SYLEKTIS to validate the technical feasibility of its concept.

The AsperCut advances itself, detects, harvests and crate white asparagus autonomously. Thanks to tests and exchanges with producers, we have identified the improvements to be made for the 2024 version.

« We are going to move from the research phase to the development phase, says Stéphane Abraham, Managing Director of SYLEKTIS. Now that we have been able to harvest asparagus with this prototype, we are going to industrialize the machine to increase its efficiency and production rates for 2024».

SYLEKTIS’ ambition is to supply a pre-series of the AsperCut for the 2024 season in order to start marketing the first machines in the second half of 2024.

The objective is to provide a robust robot, with a reduced size and at the lowest possible price to allow it to be exploited on the maximum number of plots. SYLEKTIS’ strategy is simple: provide a robot capable of performing up to 700 harvesting cycles per hour.

The AsperCut is 4 meters long by 2.5 meters wide.

It is 100% electric and aims for an autonomy of 8 hours.

Its patented design allows it to have a simple and effective tool, to manage the row cover, to be easily maneuverable thanks to its radio control and to be towed by a tractor for long trips.

The principle of operation lies in two modes: manual mode and automatic mode.

The manual mode allows the operator to bring the AsperCut to the asparagus row and to pass the asparagus row cover over the machine.

The automatic mode then selected by the operator will start the autonomous harvesting of the AsperCut on the row. Once at the end of the row, the AsperCut stops automatically to allow the operator to recover the crates full of asparagus and to position the machine in manual mode on another row.

« Launched in 2021, we proved that we could produce a robot for the selective harvesting of white asparagus in less than 2 years, according to Wilfried Garrigue, president of SYLEKTIS. Our roadmap is aggressive but achievable to provide the robot expected by farmers from 2024. We have many ideas for this machine which is a robust tool carrier straddle coupled to a harvesting block developed for white asparagus. Its uses will develop according to the needs shared with farmers. »

SYLEKTIS is now focused on the development of its AsperCut for the 2024 season.

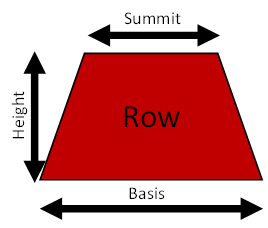

In order to take into consideration the different types of rows and your characteristics, SYLEKTIS needs your information.

Farmers, producers, do not hesitate to send the dimensions of your rows to the following email address (row height in relation to the tread, row basis width, row summit width, min and max lengths of your rows, area, maximum quantity of asparagus to harvest per day, quantity of asparagus harvested per season, single cover use, double cover use):

If you wish to be informed of the latest news from AsperCut and Sylektis, do not hesitate to send us your email address at :

Following this 2023 test season, we are preparing the AsperCut with a view to launching its marketing in 2024.

As the production quantity of AsperCuts is limited, we are now opening the pre-reservation of the first machines which will be sold in 2024 and 2025.

If you want to know more about AsperCut, do not hesitate and contact us at :